Ever heard that distinct ticking sound under the hood? That’s the lifters at work.

These small components play a huge role in engine performance, yet most drivers don’t know they exist. When lifters fail, engines lose power, burn more fuel, and make noise.

Understanding how lifters work can help car owners spot problems early and avoid costly repairs.

This article breaks down what lifters are, the different types available, and why they matter for engine health. By the end, you will know exactly what’s happening inside your engine and when to take action.

What are Lifters in an Engine and its Function

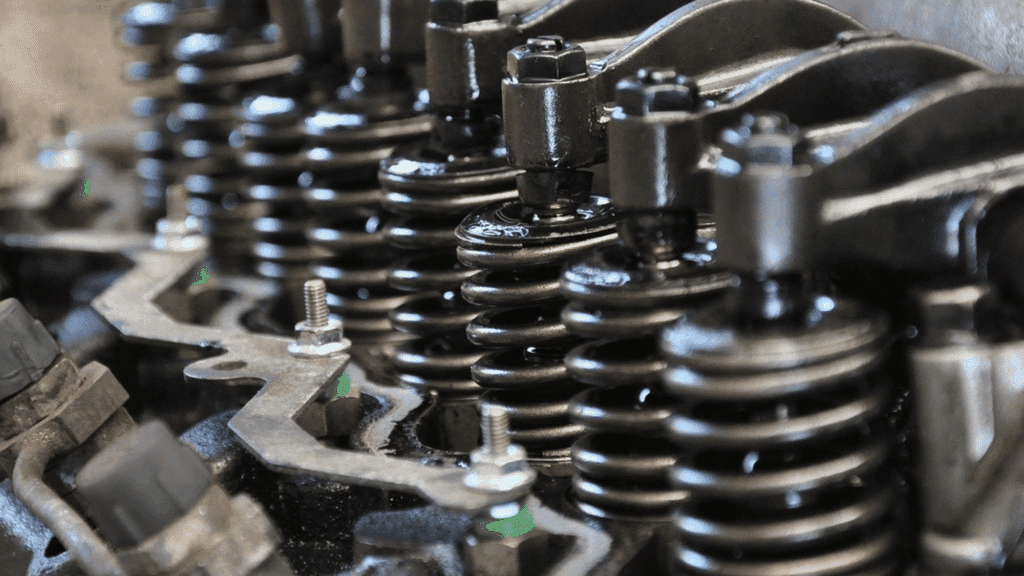

Lifters, also called valve lifters or tappets, are small cylindrical components that sit between the camshaft and the valves in an engine.

They’re located in the engine block, right above the camshaft lobes.

Their job is simple but critical. As the camshaft rotates, its lobes push against the lifters. The lifters then transfer this motion upward to open and close the engine’s valves at precise intervals.

This process allows air and fuel to enter the combustion chamber and lets exhaust gases escape.

Without properly functioning lifters, the valve timing goes out of sync. The engine can lose power, run rough, and even suffer serious damage over time.

Types of Lifters in Car Engines

Not all lifters work the same way. Engineers have developed several designs over the years, each with unique benefits.

1. Hydraulic Lifters

Hydraulic lifters use engine oil pressure inside their body to automatically adjust valve clearance. This self-adjusting feature makes them incredibly popular in modern road cars.

Drivers don’t need to check or adjust valve lash regularly, which saves time and hassle. They run quietly and deliver reliable performance for daily driving and mild performance builds.

For anyone who wants a “fit and forget” setup, hydraulic lifters are the go-to choice. They handle typical street conditions with ease and require minimal attention.

2. Mechanical (Solid) Lifters

Mechanical lifters have solid metal bodies with no oil-powered adjustment system. They require a specific amount of valve lash, and that clearance must be checked and adjusted periodically.

Racers and high-performance enthusiasts prefer them because they maintain precise valve motion even at extreme RPMs. Solid lifters can handle aggressive camshaft profiles without issues. The trade-off is more frequent maintenance.

But for anyone chasing maximum performance, that extra work is worth it. They deliver consistency and durability when engines run hard and rev high.

3. Roller Lifters

Roller lifters feature a small wheel that rides on the camshaft lobe instead of a flat surface. This design cuts friction and wear significantly.

Lower friction means the engine can use more aggressive cam shapes and rev higher without damage. Roller lifters come in two versions: hydraulic roller lifters and solid (mechanical) roller lifters.

Both types offer better performance than flat-faced designs. They’re common in performance builds and newer engines where efficiency and power matter. The roller design simply handles stress better than older styles.

4. Flat Tappet (Flat-Bottom) Lifters

Flat tappet lifters use a flat or slightly crowned face that slides directly on the cam lobe. This traditional design has been around for decades.

Flat tappets can be hydraulic or mechanical, depending on the application. They’re more sensitive to break-in procedures and oil quality compared to roller lifters.

But they still appear in many classic engines and budget performance builds.

Cost is a big factor; flat tappets are cheaper to manufacture and replace. With proper care and the right oil, they provide solid, reliable service.

How the Lifter in the Engine Works

Understanding how lifters function helps car owners recognize problems early. The process happens thousands of times per minute, turning rotational camshaft motion into precise valve movements. Here’s how it works step by step.

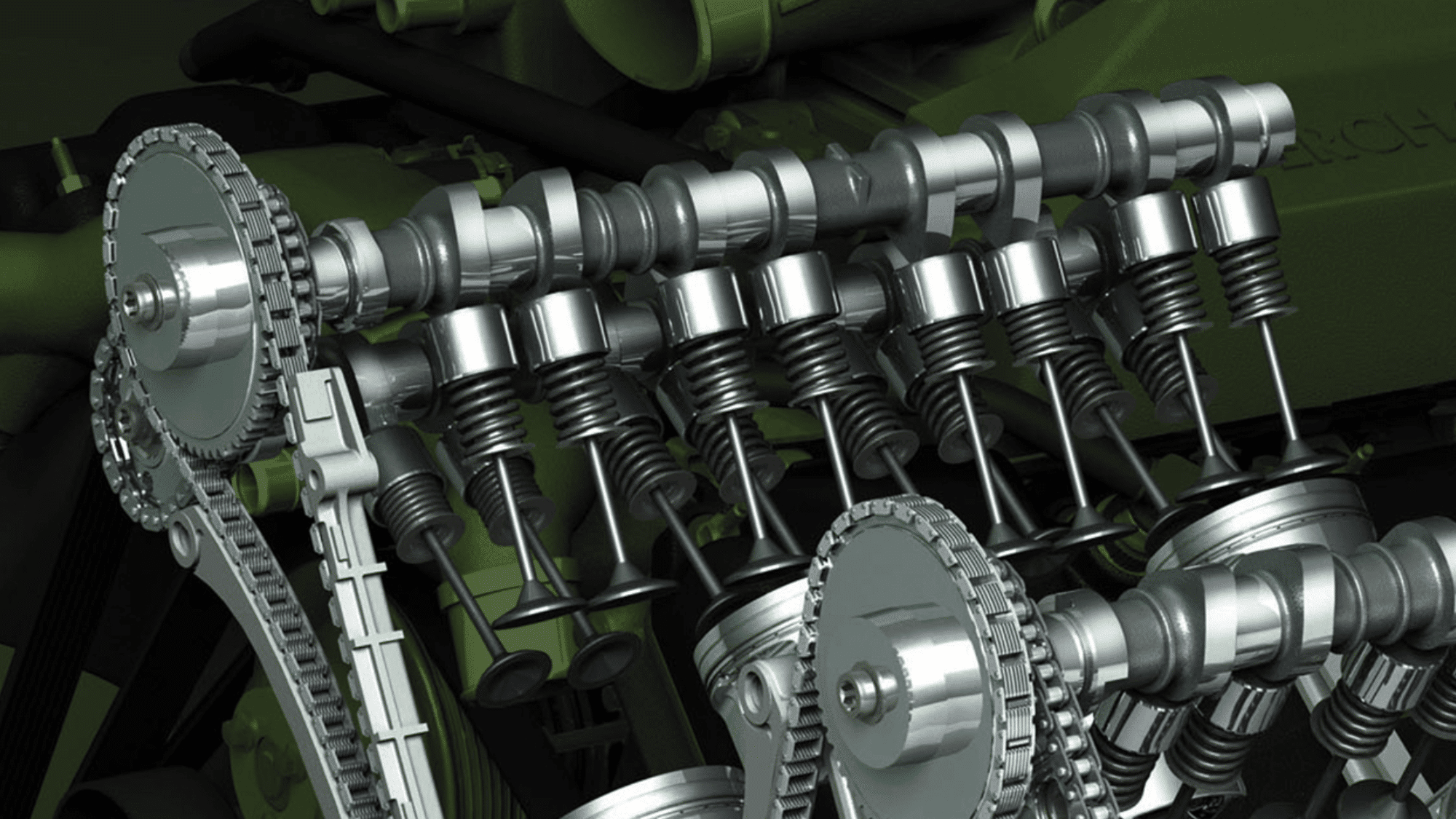

Step 1: The camshaft rotates as the engine runs. Each lobe on the camshaft is shaped to control valve timing.

Step 2: The cam lobe pushes against the bottom of the lifter. This upward force starts the valve-opening sequence.

Step 3: The lifter transfers motion through the pushrod (in pushrod engines) or directly to the valve (in overhead cam engines).

Step 4: The pushrod activates the rocker arm, which pivots and pushes the valve open.

Step 5: The valve opens, allowing the air-fuel mixture in or the exhaust gases out.

Step 6: As the cam lobe rotates away, spring pressure closes the valve, and the lifter returns to its resting position.

Why Lifters are Important for Engine Performance

Lifters might be small, but they control one of the engine’s most critical functions. They ensure valves open and close at exactly the right time.

When lifters work properly, the engine breathes efficiently, burns fuel completely, and produces smooth power. Good valve timing means better fuel economy, lower emissions, and maximum horsepower. But when lifters wear out or fail, the entire system suffers.

Valves may not open fully or close completely. This leads to rough idling, power loss, and increased fuel consumption.

In severe cases, faulty lifters can cause valve-to-piston contact, resulting in catastrophic engine damage. Regular maintenance keeps lifters functioning correctly and protects the engine’s long-term health.

Real Stories and Expert Advice on Engine Lifters

Car enthusiasts and mechanics often share their experiences with lifters online.

One expert explains,

“Lifters ride on the camshaft and push on the pushrods to open the valves.”

This simple description captures their core function. Another mechanic notes that hydraulic lifters

“are full of oil, and are pressurized by your oil pump. These lifters adjust themselves to take slack out of the valvetrain so you don’t have to do it manually.”

However, he warns they

“can collapse at high rpm or when you use very stiff valve springs.”

When discussing maintenance, one technician points out that accessing lifters

“takes some work. The whole throttle body and intake will have to be removed along with the valve covers, push rods, and rocker arms.”

These real-world insights help owners understand both the benefits and challenges of lifter maintenance.

Common Lifter Problems and Maintenance

Even quality lifters wear out over time. Recognizing the warning signs early prevents expensive engine damage. Regular maintenance and quick action keep lifters working smoothly and extend engine life significantly.

| Problem | Symptoms | Causes | Solution |

|---|---|---|---|

| Lifter Tick/Noise | Tapping or clicking sound at idle or acceleration | Low oil level, dirty oil, worn lifter faces | Check oil level, change oil, inspect lifters |

| Collapsed Lifter | Misfires, rough idle, power loss | Internal hydraulic failure, high mileage | Replace affected lifters, check oil pressure |

| Stuck Lifter | Valves stay partially open or closed | Oil sludge buildup, contamination | Clean valve train, use engine flush, replace lifters |

| Excessive Wear | Grinding noise, metal shavings in oil | Poor lubrication, aggressive cam profiles | Replace lifters and inspect the camshaft for damage |

| Oil Pressure Issues | Lifter noise increases with RPM | Worn oil pump, clogged passages | Fix the oil system, replace the pump if needed |

To Conclude

Lifters may work behind the scenes, but their impact on engine health is undeniable.

Proper maintenance, like regular oil changes and listening for unusual sounds, keeps these components functioning for years.

Ignoring lifter problems leads to poor fuel economy, loss of power, and potentially serious engine damage. Car owners who understand how lifters work can make smarter maintenance decisions and catch issues before they escalate.

Taking care of these small parts protects the entire engine. Keep the oil clean, address strange noises quickly, and the lifters will keep doing their job reliably.